A processing and manufacturing enterprise mainly engaged in precision mechanical parts processing

- More than 200 various machine tools including CNC lathes, machining centers, honing machines, and centerless grinders

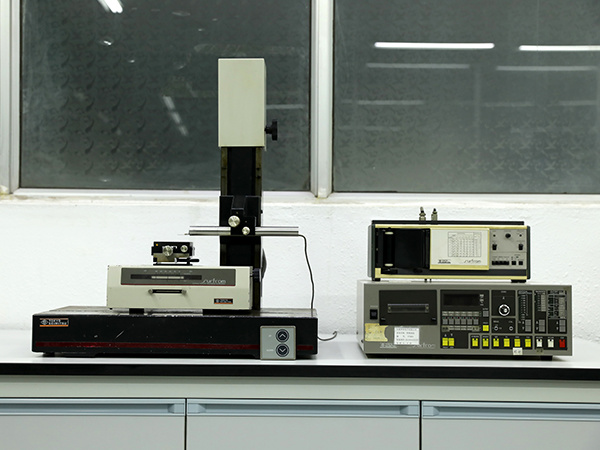

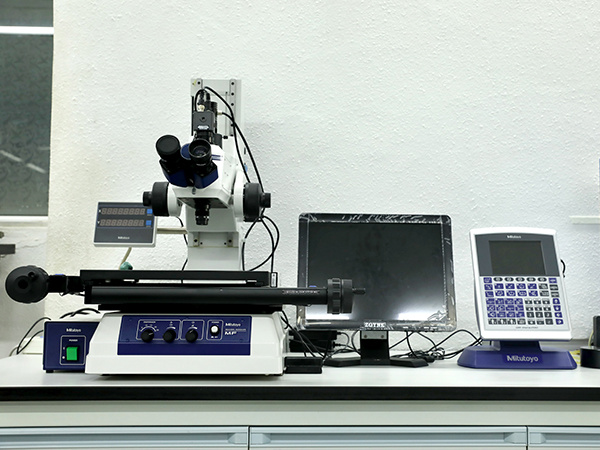

- Equipment such as coordinate measuring machines, profilometers, cylindricity testers, video measuring machines, automated inspection, and cleanliness testing systems

- ISO9001 Quality Management System Certification / IATF16949 Quality Management System Certification / IEC27001 Information Security Management System Certification and ISO14001 Environmental Management System Certification

Simple 3-step process to quickly get a quote

Step 1: Leave your information, our experts will contact you within 24 hours.

Step 2: Confirm your drawings, select your production process and materials.

Step 3: Receive the quote and production delivery schedule.

Customized according to your design, we can do much more than this.

Armature series

Armature series

Bar processing

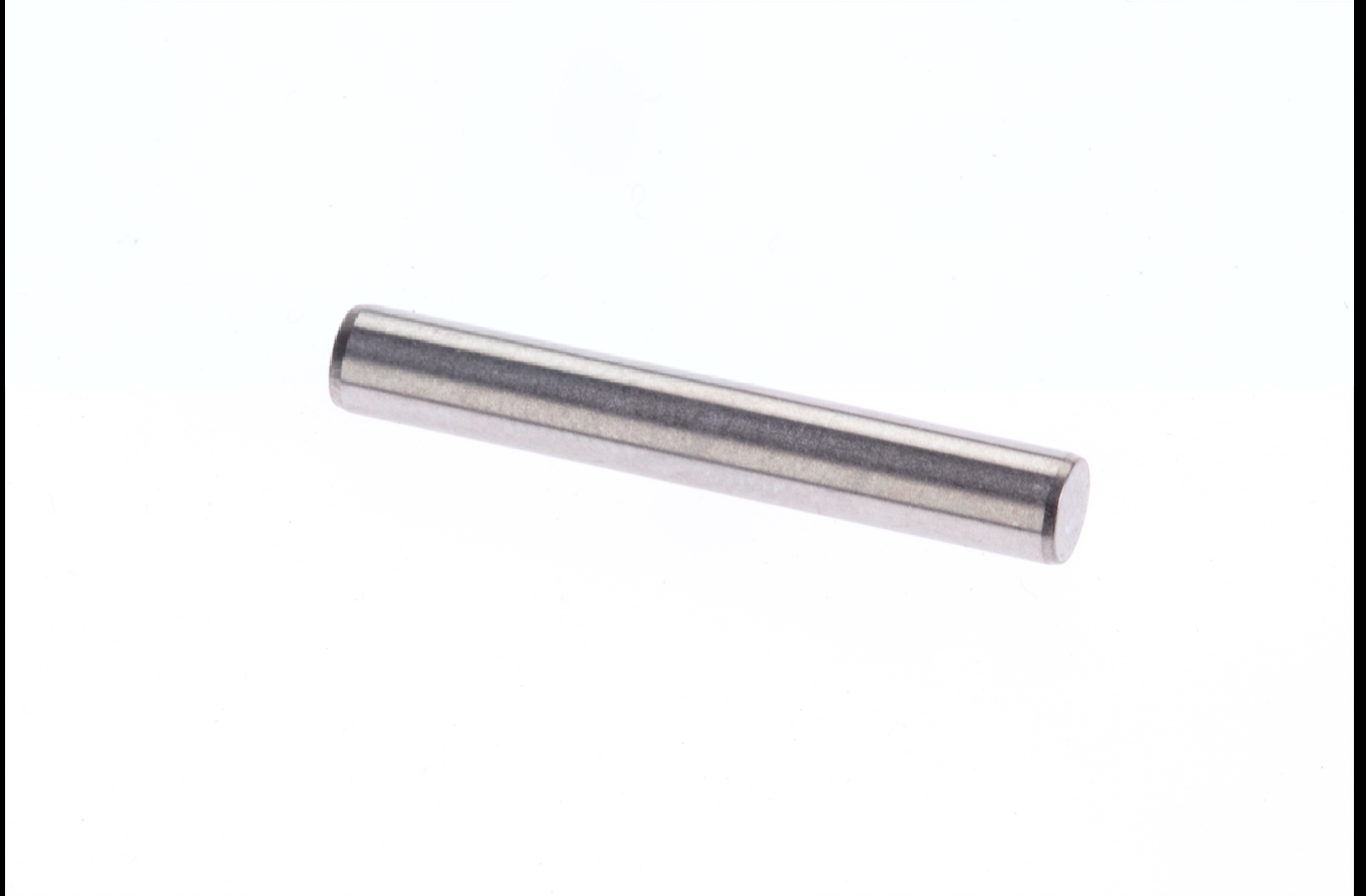

Push needle shaft series

Push needle shaft series

Pipe processing

Push needle shaft series

Push needle shaft series

Shaft machining

Armature series

Armature series

Gas nitriding parts

Aluminum parts

Stainless steel parts

Automobile parts

By choosing our customization services, we can provide you with the following conveniences.

General Field

· Flexibility: Custom design and manufacturing of precision mechanical parts to meet exact project or product requirements.

· Optimized Design: Custom manufacturing tailored designs to improve performance and efficiency in specific applications.

· Improved Quality: Strict quality control ensures the reliability of custom production.

· Cost Reduction: Custom designs minimize waste and improve production efficiency, thereby reducing costs over time.

About Shenhua

In recent years, Shenhua has focused mainly on processing key components of automotive engine fuel injection systems and medical device parts. Design and processing products serve customers in the USA, Japan, Europe, and other regions.

Equipment Owned

Industry Experience